By Nijes Uparati

Augmented Reality (AR) and Virtual Reality (VR) are buzzwords these days; literally every magazine and newspaper has articles boasting the AR/VR craze. But where do we really stand on the AR/VR development? What are its implications? And what sort of applications should we really seek? These are questions troubling the scientists and developers alike who delve deeper into their disciplines to invent and design technologies that are on par with current technological needs.

Just as a brief overview: VR is a interactive technology generated within a simulated environment that embraces the elements of real world but limits interactions within the digital. AR on the other hand is a technology that allows the augmentation of our everyday interaction with real world with various sensory modalities such haptics, auditory or visual. We are going to alternate between both technological sides to post mixed finding on the subject matter.

How is the art world benefited by the recent advances in VR/AR technology?

Recently a digital museum opened in Tokyo, Japan. This museum is a collaborative work of individuals from various disciplines including computer science, art, and human-computer interaction to name a few. The museum, hosted in a space of 10,000 square meter, is operated by using the about 520 computers and 470 projectors working in sync to create amazing visual experience for the visitors.

VR as an Art Medium

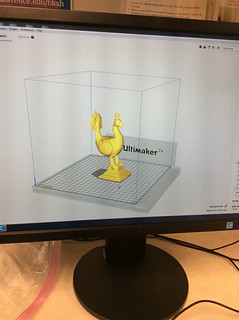

Recent advances in VR technology has paved ways for exploring the art domain with mediums that are far from the traditional. One such technological breakthrough is the idea of art in 3D digital space. Google’s Tilt brush technology combined with commercially available VR headsets like HTC VIVE and OCULUS RIFT could equip artists with an entirely new way to explore the art world.

At a

At a