Boldt Construction has been a Lawrence University construction partner for many years. Boldt states on their Website that Safe construction requires a holistic approach. “We don’t buy the idea that incidents are part of the job.” To build safely, we must focus on eliminating:

- SHORTCUTS – avoiding unintended consequences

- DISTRACTIONS – keeping focused on safe practices

- REWORK – ensuring adequate timelines

- NEAR MISSES – anticipating potential dangers

- INJURIES – equipping everyone to build their best life

(APPLETON, WI) On March 18, 2021- The Boldt Company has received a Platinum Safety Award from ConstructSecure, Inc. This award is presented to companies that register a safety score 95% or greater in the Safety Assessment Program administered by ConstructSecure.

We can follow the Boldt Company example in striving for “0 zero today – INJURIES – SHORTCUTS – DISTRACTIONS”

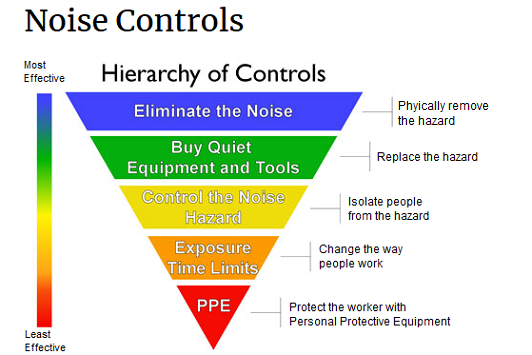

To achieve zero injuries, we must learn to recognize hazards and control the risk of working in hazardous areas. Working around a construction site requires us to be alert to our surroundings, paying attention to safety signs posted to keep us safe.

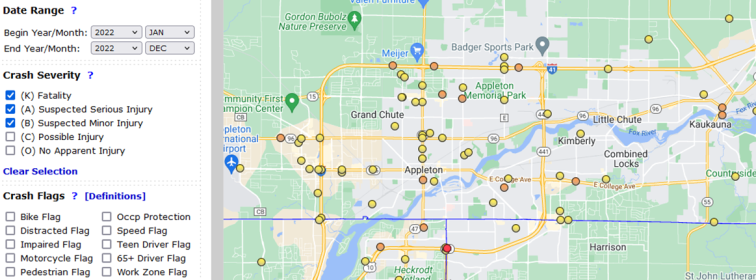

This summer the Lawrence University campus will have many construction projects in progress at the same time. Only authorized personnel wearing the proper safety equipment are allowed in construction zones. Ask your supervisor if you need more information about a building project that affects you.

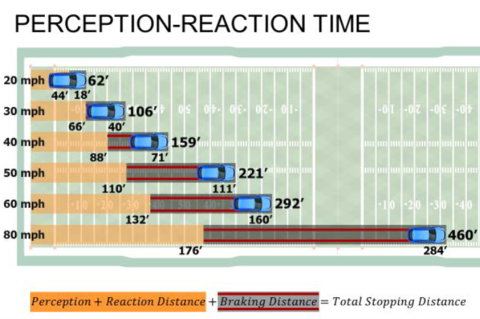

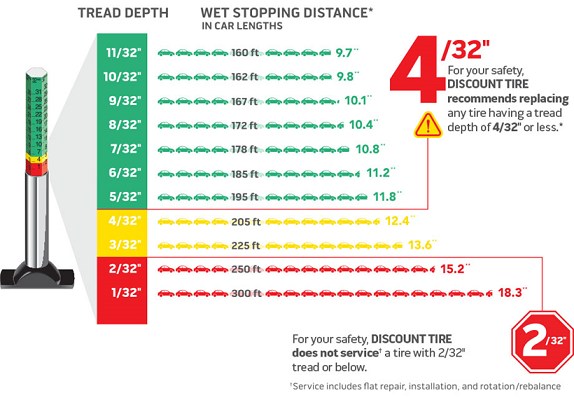

Pedestrians have the right-of-way. Drive SLOW when driving golf carts or vehicles on sidewalks or on fire lanes in-between buildings. Maintain at least 3 feet or more between the vehicle and pedestrians, be prepared to stop as you approach pedestrians exiting buildings, changing their walking pace or direction.

ALWAYS CHECK BEHIND THE GOLF CART or VEHICLE BEFORE BACKING.

To AVOID distractions while driving on campus, pull over in a safe place and stop vehicle before using a cell phone or answering a phone call.

As we work on campus during this busy summer, remember to strive for ZERO injuries, shortcuts, and distractions.

Let us prepare to work safely in the many different tasks that will be performed this summer.

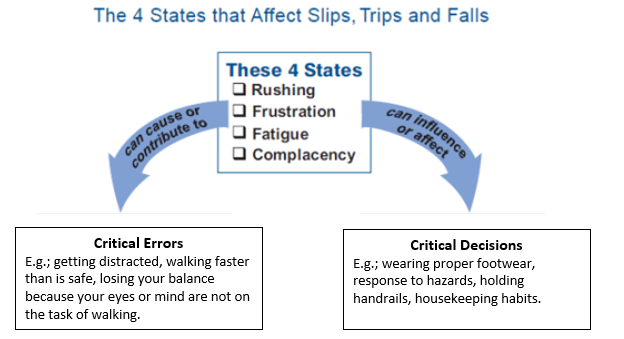

Following the SafeStart method of checking that we are not in any of these four mental states. Rushing – Frustration – Fatigue – Complacency can affect how we perform a task, even a simple task like walking.

Making poor critical decisions can lead to critical errors in many of the tasks performed on campus, not only walking (and these errors can cause or contribute to injuries). Our attention must be focused on the task at hand, especially when working on or repairing equipment.

Following manufactures guidelines and procedures insures that we are performing the task in a safe manner. Paying attention to details and warnings in instructions will help us as we strive for ZERO injuries, shortcuts, and distractions.

Sources: https://www.boldt.com, https://safestart.com/guides/