Understanding common electrical hazards can help you identify areas for improvement in your surroundings and prevent future injury. Here are several examples:

- Poorly installed, faulty and/or ill-maintained electrical equipment.

- Faulty wiring.

- Overloaded or overheated outlets.

- Use of flexible leads and extension cables.

- Incorrect use of replacement fuses.

- Use of electrical equipment with wet hands or near the source of water.

- Working near overhead power lines.

Tips to prevent workplace electrical incidents

Electricity can become dangerous if not handled properly. Electricity flowing through a conductor contained in its insulated circuit is necessary for normal daily work activities and mechanical equipment.

It is important to follow these safety tips for preventing workplace injuries:

- Unplug or switch off electrical appliances when not in use or while cleaning, repairing or servicing.

- Ensure that all electrical appliances are turned off at the end of the day.

- Don’t forcefully plug into an outlet if it doesn’t fit.

- Refrain from running electrical cords across doorways, under the carpets, or in high foot traffic areas.

- Maintain a clearance of at least 3 feet from all electrical panels.

- Use only equipment that is double-insulated and properly grounded.

- Don’t overload the electrical outlets.

- Ensure that two extension cords are not plugged together.

- Only use electrical equipment that is approved by a national testing laboratory.

- Pay attention to the warning signs when operating equipment. Equipment may heat up, spark, smoke or make weird noise; identify the signs and immediately take it out of service.

- Regularly check for defects in cords and equipment. Report immediately if any and take out of service.

- While unplugging, grip the plug and pull. Don’t pull the cord from a distance.

- Do not use electrical equipment or appliances with wet hands or near water and wet surfaces.

- Inspect the outside work areas for overhead power lines before erecting ladders outside, keep at least 10 feet away from power lines.

- Follow the warnings posted on signs near potential electrical hazards, such as electrical panels, and high voltage areas.

Please read these three case studies on how electrocutions can happen.

FACE Report: Worker electrocuted while replacing light fixture

December 20, 2020

Case report: #2018OR40

Issued by: Oregon State Fatality Assessment and Control Evaluation (FACE) Program

Date of incident: Sept. 26, 2018

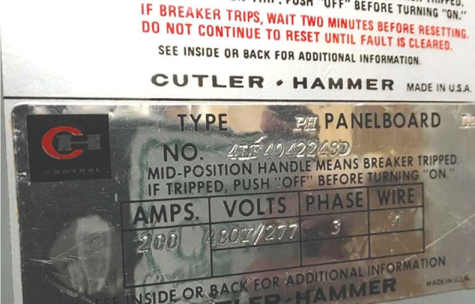

A 28-year-old lighting technician, employed three weeks with a staffing agency and with no electrical trade experience, was electrocuted while working on an energized lighting fixture. He was part of a crew of subcontracted technicians replacing lights at a large retail store chain during a night shift while the lighting circuits were energized. Workplace hazards at the store were not identified, and a trained competent person was not onsite. The foreman believed the lights were on a 208/120-volt single-phase panel, but they were on an energized 480/277-volt three-phase panel. At the time of the incident, the victim was working on a fixture without a quick disconnect. Around 3:30 a.m., co-workers saw the victim slumped over a scaffold, not moving. CPR was initiated and co-workers called 911. Emergency medical services arrived and pronounced the victim dead at the scene. After the victim was removed and law enforcement left, the foreman and remaining crew continued to work, completing the disconnect installation the victim was working on, exposing themselves to similar – and potentially fatal – hazards.

To help prevent similar incidents, employers should:

- Employers should provide written procedures and training to ensure workers are able to safely perform potentially hazardous tasks.

- Have a competent person onsite to identify and mitigate safety hazards, and to stop work when an injury occurs.

- Require that workers de-energize circuits and use lockout/tagout procedures before performing work.

FACE Report: Field technician electrocuted after contacting downed power line

November 28, 2021

Case report: #20KY065

Issued by: Kentucky State Fatality Assessment and Control Evaluation Program

Date of incident: Nov. 4, 2020

A 31-year-old field technician was part of a two-person engineering crew tasked with surveying power lines in a residential area with homes located on each side of a two-lane highway. The technicians worked their way from pole to pole, collecting data such as pole height, distance between poles and each pole’s proximity to the highway. During the course of their duties, the technicians encountered a downed power line, likely the result of a recent windstorm. The downed power line was entangled in a nearby tree that stood about 8 feet from the utility pole. After the victim located the downed line, he worked to free it from the tree. Although the line was not initially energized, it became energized at some point during the untangling process and delivered an electric shock to the victim, killing him instantly. The cause of death was listed as high-voltage electrocution.

To help prevent similar occurrences, employers should:

- Consider developing policies and procedures that specify the standard operating procedures for employees who encounter a downed power line.

- Perform a job hazard analysis.

- Provide hazard awareness training to employees annually.

FACE Report: Father and son painters killed when ladder contacts power line

February 20, 2022

Case report: #71-210-2021

Issued by: Washington State Fatality Assessment and Control Evaluation Program

Date of report: Nov. 7, 2020

A 55-year-old painting contractor and his 27-year-old son were electrocuted when the aluminum extension ladder they were moving contacted an overhead power line. On the day of the incident, the wind was blowing 15-30 mph, with gusts up to 40 mph. The crew had finished painting for the day and was cleaning up the site. The contractor and his son were moving the ladder, which was at its full extension of 48 feet. The two were holding the ladder in a vertical position as the son attempted to retract the ladder’s extension. A gust of wind blew the ladder into a 14,460-volt overhead power line, and an electrical current traveled from the power line through the ladder and through both workers. The contractor died at the scene. His son died nearly a month later.

To prevent similar occurrences, employers should:

- Identify the location of overhead power lines as part of an initial worksite survey for jobs involving the use of ladders. Note power line heights and distances from work areas on site diagrams.

- Perform a job hazard analysis of the worksite.

- Use non-conductive ladders around power lines.

- Lower extension ladders and transport them horizontally.

- Be aware of windy conditions while moving a ladder near power lines.

Sources:

https://safety-culture-training.com/uploads/pdfs/Week18safetytopics-ElectricalSafety.pdf;

Fatality Assessment and Control Evaluation (FACE) Program – https://www.cdc.gov/niosh/face/default.html