We’ve had lots of interesting uses of our makerspace by Studio Art students for both senior exhibits and assignments. Here are some examples:

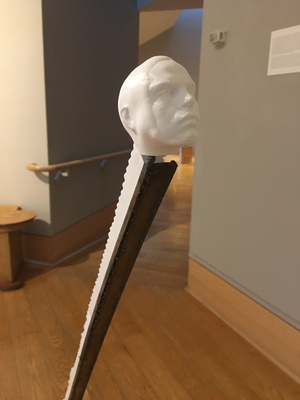

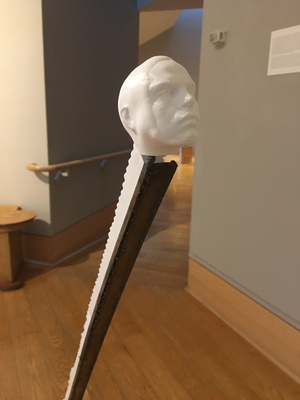

Quantified Actualization by Penn Ryan

Penn Ryan ’18 spent a lot of time in the makerspace meticulously designing and 3D printing stairs for his piece, “Quantified Actualization”. The top part of this piece was designed using a 3D scan of his face, scanned and printed in the makerspace. In his artist statement, he describes this work as a commentary on fitness tracking,

…”This staircase is the combined product of 5 months of tracking. Fitness tracking is often an obsessive practice. Quantifying one’s accomplishments gives someone a feeling of control over their body. Users feel that technology can give them insights into how well they are taking care of their body and therefore meeting their goals. These goals are often initially physical but become mental and occupational and all encompassing. Whether or not one is striving for improvement and accomplishing it becomes a moral judgement. Self-actualization is the ultimate goal.”

More photos, and a complete artist statement can be found in the 2018 Senior Exhibit Gallery.

The Lost Man’s Fortune by Alison Smith

Alison Smith ’17 created an installation that spread across the exterior of the Wriston Art Center and inside the senior gallery exhibit. Alison used vinyl decals to create 8-bit video game inspired art scenes, as well as used the Silhouette cutter to create paper items and treasures, also inspired by video games. Her statement explains, “this installation gives physical forms to video game objects and environments in order to change the way we interact with them through the completion of a real-life, video game inspired quest.”

More photos of installation of The Lost Man’s Fortune can be found in the 2017 Senior Exhibit Gallery.

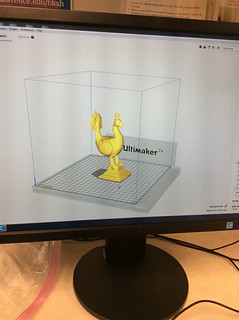

Installation View of Mystery Ocean by Noah Gunther

Noah Gunther ’17 used the makerspace to 3D print objects for both his junior show and senior show. In both, he created virtual worlds, and brought the virtual to physical using the 3D printers. For his senior show, he integrated a virtual reality headset to let the viewer further immerse themselves in the world he created. We asked Noah to tell us a little about using 3D printers as an artist- here’s what he had to say,

“…I’ve been interested in the intersection of what we think of as “real life” and the world of computer simulation for a long time. Having access to 3D printers has been an excellent way for me to explore this connection — I build 3D models on the computer, which I then add to a computer simulation where a user can virtually interact with them. I then also 3d print the models in the same colors I display the virtual models, allowing for a direct connection between the virtual objects and the 3D printed ones. Being able to 3D print these items allows me to explore the connection between virtual and real interaction in a way I otherwise wouldn’t be able to!”

Innovating a Legacy: Alice Parker by Aedan Gardill

Aedan R. Gardill ’18 painted a series of African American women inventors and innovators and created representational installations to accompany each painting. For Alice Parker, Aedan used the Silhouette cutter to create a vinyl display to represent her contributions to modern thermostats. He describes his series of paintings and installations as, “Sharing the stories of these women and increasing the visual representation of non-male, non-white scientists is a step forward to changing the negative cultural perspective of women in the sciences.”

More selections from the installation, Innovating a Legacy can be found in the 2018 Senior Exhibit Gallery.

Installation and paintings by Nina Sultan

Nina Sultan ’17 included interviews by portrait subjects with her paintings on display for her senior show. The interviews were played on iPads on loan from the makerspace. In her artist statement, Nina describes her works as, “Inspired by people from the Appleton community, through painting, photography, and audio documentation, the work seeks to create thoughtful narratives to unmask, appreciate, and better understand our personal connections on a deeper level.”

More photos of the installation can be found in the 2017 Senior Exhibit Gallery.

Speaking of these many student shows in the Wriston Galleries, gallery curators uses the makerspace’s Silhouette Cameo electronic cutter to create titles for their exhibits. It saves a great deal of money compared to requesting to have them made by an outside sign shop.

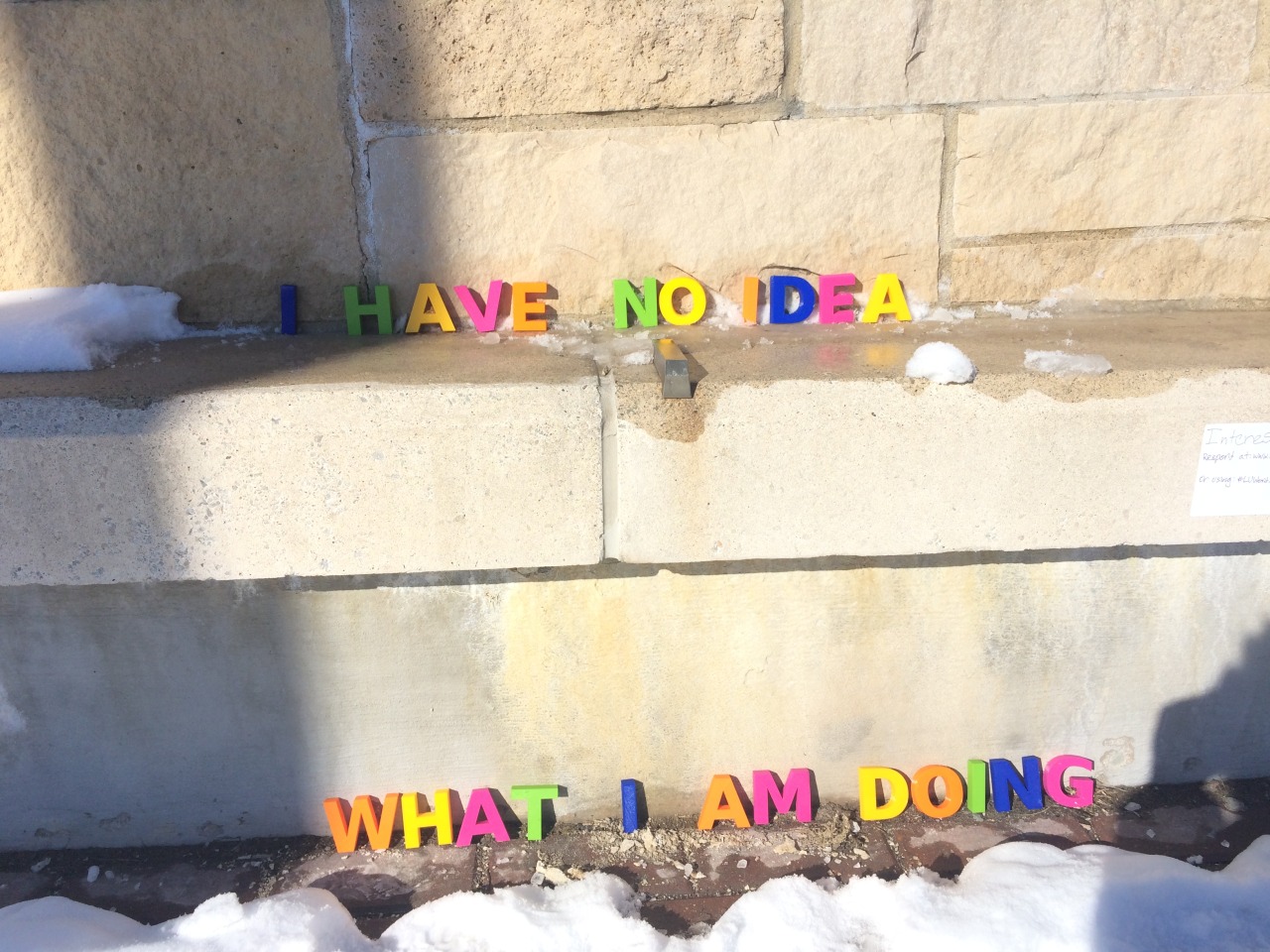

Word Art by Sara Morrison

Many other students have used the makerspace tools and equipment for projects related to art course assignments. Here are just a few:

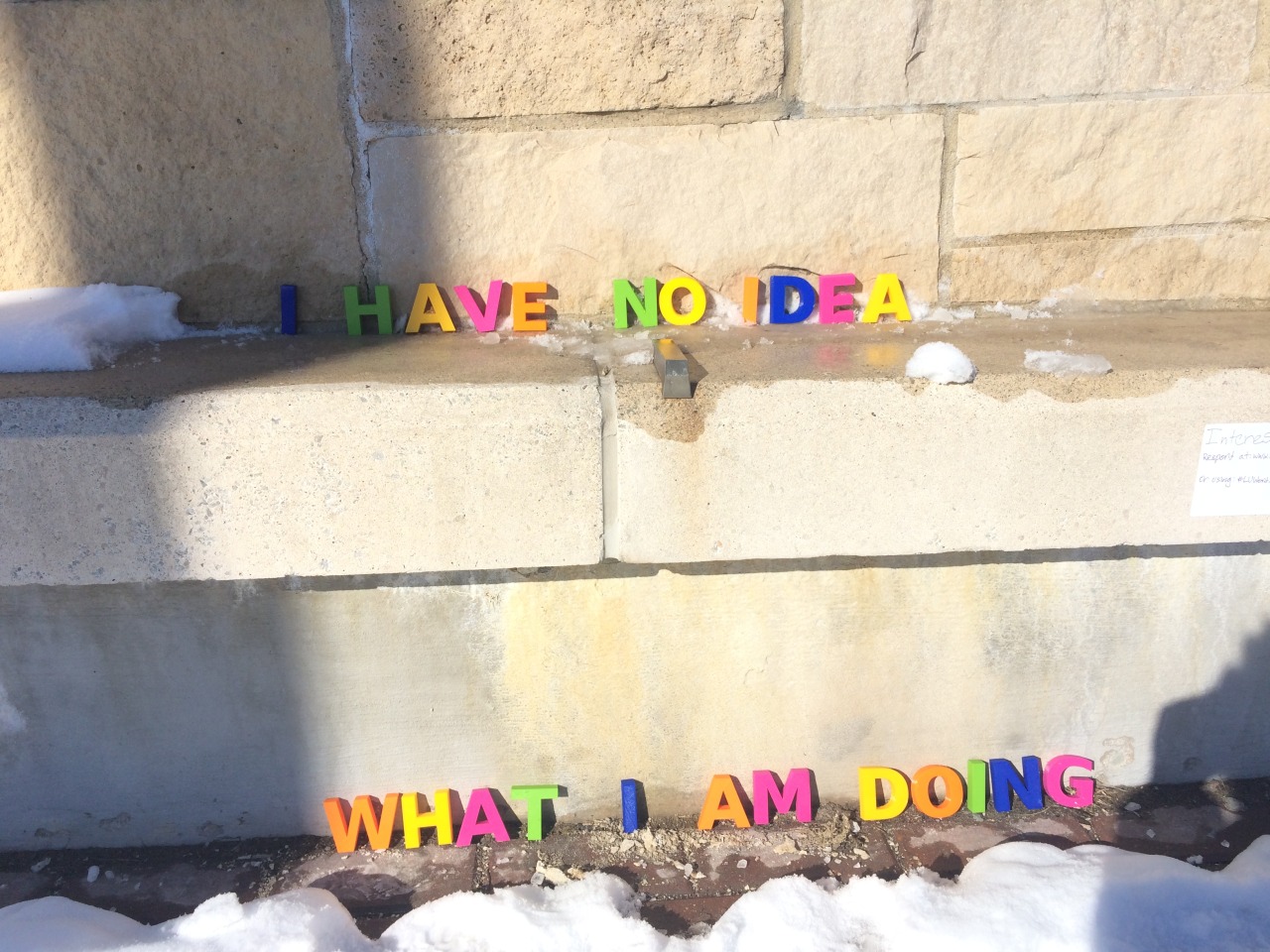

Sara Morrison ’18 created a series of word art that she displayed around campus for her New Media in Art assignment. She used the 3D printer and electronic cutter to create letters from PLA filament and vinyl.

Sara encouraged members of the Lawrence University community to take photos of the word art (as she left it, and as it had been changed by others) and post them to her Tumblr page, LU Word Art.

Stencil by Malcolm Lunn-Craft

Malcolm Lunn-Craft ’17 used the electronic cutter to create stencils for his painting class. The adhesive vinyl helped with his assignment medium of spray paint.

While not created in the makerspace, Malcolm’s powerful photographs from his senior exhibit are available to view in the 2017 Senior Exhibit Gallery (content warning: visual allusion to violence).

See more uses of the makerspace by Studio Art students and faculty on our Makerspace Assignments at LU page, as well as on our Instagram and Twitter.

At a

At a